New Learn More

What are Biological Weapons?

What are Biological Weapons?

What are Gas Masks?

What are the different types?

How Gas mask Filters Work?

What are ME.ST.EL SGE Gas Masks?

Facts about ME.ST.EL Products

ME.ST.EL Certifications & Approvals

What are ME.ST.EL Product Features?

How to wear & use?

Fixing Rim and Strap

Cleaning & Decontamination

How to measure my Vest Size?

How to measure my Helmet Size?

There are a variety of micro-organisms that can be used as biological weapons. Agents are commonly chosen because they are highly toxic, easily obtainable and inexpensive to produce, easily transferable from person to person, can be dispersed in aerosol form, or have no known vaccine. Below is a list of a few potential biological organisms that may be used as biological weapons.

|

Bacillus anthracis |

Soil | Humans, Domestic Animals | Open Wounds, Inhalation |

Pulmonary Anthrax Septicemia, Flu-like symptoms |

|

|

Soil | Humans | Contaminated Food or Water, Inhalation |

Weakness, Double Vision and Vertigo, Difficulty in Speaking, Swallowing, and Breathing, Muscle Weakness |

|

|

Intestines of humans and other animals, Soil |

Humans, Domestic Animals | Open Wounds | Gas gangrene, Severe Abdominal Cramps, Diarrhea |

|

Protein toxin |

Extracted from Castor Bean Plants | Humans | Contaminated Food or Water, Inhalation, Injection |

Severe Abdominal Pain, Watery and Bloody Diarrhea, Vomiting, Weakness, Fever, Cough, and Pulmonary Edema |

|

Variola Virus |

Eradicated from Nature, Now Obtained from Laboratory Stockpiles |

Humans | Direct Contact with Bodily Fluids or Contaminated Objects, Inhalation |

Persistent Fever, Vomiting, Rash on Tongue and in Mouth, Rash and Bumps on Skin |

For more information on biological weapons please see:

Chemical and Biological Weapons Resource Page

Potential Biological Weapons Threats

What are Gas Masks?

Gas masks -- more generically known as Respirators -- are the ones to think about after a chemical or biological attack. It has also an important part of industrial safety on a daily basis. They protect workers against everything from flour dust in a grain elevator to the damaging organic chemicals in paint spray.

What are the different types?

When most people think about gas masks or respirators, what they usually envision is a tight-fitting plastic or rubber face mask with some sort of filter cartridge. The mask covers the nose and mouth. These are called half-mask air-purifying respirators. Depending on the chemical or biological agents in the environment, a half mask may not be sufficient because the eyes are very sensitive to chemicals and offer an easy entry point for bacteria.

How Gas mask Filters Work?

Any respirator that you are likely to use will have a filter that purifies the air you breathe. How does the filter remove poisonous chemicals and deadly bacteria from the air?

Any air filter can use one (or more) of three different techniques to purify air:

- Particle filtration

- Chemical absorption or adsorption

- Chemical reaction to neutralize a chemical

Note : A typical disposable filter cartridge for a respirator: When you inhale, air flows through the inlet on the left, through a particulate filter, through an activated charcoal filter, through another particulate filter (to trap charcoal dust) and through the outlet on the right into the mask. When the particulate filter clogs or the activated charcoal becomes saturated, you must replace the cartridge.

Particle filtration is the simplest of the three. If you have ever held a cloth or handkerchief over your mouth to keep dust out of your lungs, you have created an improvised particulate filter. In a gas mask designed to guard against a biological threat a very fine particulate filter is useful. An anthrax bacteria or spore might have a minimum size of one micron. Most biological particulate filters remove particle sizes as small as 0.3 microns. Any particulate filter eventually clogs, so you have to replace it as breathing becomes difficult. A chemical threat needs a different approach, because chemicals come as mists or vapors that are largely immune to particulate filtration. The most common approach with any organic chemical (whether it be paint fumes or a nerve toxin like Sarin) is activated charcoal.

Charcoal is carbon. Activated charcoal is charcoal that has been treated with oxygen to open up millions of tiny pores between the carbon atoms. According to Encyclopedia Britannica: The use of special manufacturing techniques results in highly porous charcoals that have surface areas of 300-2,000 square meters per gram. These so-called active, or activated, charcoals are widely used to adsorb odorous or colored substances from gases or liquids.

The word adsorb is important here. When a material adsorbs something, it attaches to it by chemical attraction. The huge surface area of activated charcoal gives it countless bonding sites. When certain chemicals pass next to the carbon surface, they attach to the surface and are trapped. Activated charcoal is good at trapping carbon-based impurities ("organic" chemicals), as well as things like chlorine. Many other chemicals are not attracted to carbon at all -- sodium and nitrates, to name a couple -- so they pass right through. This means that an activated-charcoal filter will remove certain impurities while ignoring others. It also means that, once all of the bonding sites are filled, an activated charcoal filter stops working. At that point you must replace the filter.

Sometimes, the activated charcoal can be treated with other chemicals to improve its adsorption abilities for a specific toxin. The third technique involves chemical reactions. For example, during chlorine gas attacks in World War I, armies used masks containing chemicals designed to react with and neutralize the chlorine. Destruction by chemical reaction was adopted in some of the earliest protective equipment such as the 'hypo helmet' of 1915 (chlorine was removed by reaction with sodium thiosulfate) and in the British and German masks of 1916 (phosgene was removed by reaction with hexamethyltetramine). In industrial respirators, you can choose from a variety of filters depending on the chemical that you need to eliminate. The different filters are color coded by NIOSH standards for things like acids and ammonia.

ME.ST.EL is a Company that has 54 years of experience molding rubber goods and working in several different markets. The following are some of the products produced:

- Fashionable watch rubber, silicone, plastic, multi- compound components

- Diving equipment

- Military protection equipment

- Respiratory PPE

- Molding of silicone, liquid silicone, rubber, plastic and thermoplastic goods

- Engineering and manufacturing of molds for rubber/silicone and plastic

ME.ST.EL has a financial office in Milan, Italy, 2 Manufacturing plants of 10,000 and 20,000 sq/feet in Genoa Italy and one factory (6000 sq./feet) in San Diego, CA – USA. ME.ST.EL is an ISO 9001-2000 certified company and also a NATO classified supplier. We are a proud seller of quality MESTEL products for civilian and law enforcement units.

Mustard Gas Resistance

Mustard gas penetration on the SGE masks, and in particular on the butyl rubber face-seal of the SGE 150 and SGE 400/3 BB masks and the visor coating on the SGE 400 – SGE 400/3 - SGE 400/3 BB masks, had the following results:

- Sample shape: round ,diam. 44 mm

- Test conditions: 30 C, mustard gas,

- clorobenzene = 80:20

Visor

(#1), 2.30mm thickness-go through as gas = > 50 h

(#1), 2.30mm thickness-go through as gas = > 50 h

Face seal

(#3), 2.68mm thickness-go through as gas = > 50 h

(#3), 2.68mm thickness-go through as gas = > 50 h

(#3), 2.68mm thickness-go through as gas = > 50 h

The SGE masks are fully resistant to all used means of decontamination, including boiling water.

Carbon Dioxide Content

- (Inhaled air) 0.44%

Field and Quality of Vision

The full transparent body allows a much wider field of vision. The quality of vision is not impaired in cold environment. The SGE masks are supplied with an easily removable corrective lens system using standard lenses.

Field of Vision

(Eye area only)

- Total (red + pink + yellow) 87%

- Stereo field (pink) 80%

Fogging up of Visor

(Tested up to –30° C.)

- Starting cold no fogging up

- Starting warm no fogging up

Light Transmittance - 92%

Communication

Microphone, earphones and hearing protection devices can be easily fitted to the mask. Due to the position and type of speech membrane, loud speaker use is easy and efficient.

Protection against Conventional Weapons

The visor protects not only the eyes, but the whole face against fragments, stones, splinters caused by explosions. It can stand with no damage (break or perforation) to the impact of a steel sphere 6.35 mm caliber bullet hitting the mask at any point at the speed of more than 150 m/sec. Blast effects do not impair the protection performances as all the membranes are able to stand significant pressure. The speech diaphragm in particular is the open type and does not use the old rigid metal membrane.

Heat Resistance

The masks in all their parts are flame resistant and heat-radiation resistant. It does not melt or catch fire when tested accordingly with the EN 136 specification and the German Fire-Brigade radiation test. (800 C. temp. of flame for 5 sec. 200 C. temp. for 6 minutes).

Drinking Facilities

The SGE 400, 400/3, & 400/3 BB may be supplied with a drinking system.

How to wear and Use?

The SGE masks have been developed to provide 5 days of continuous wearing. Thanks to the new concept of rigid body, it has been possible to adopt an exceptionally comfortable face-Seal.

Leakage & Test/Sizes

The Protection factor allowed by the SGE masks have been proved by several certification laboratories worldwide. The most recent survey has been made by SBCCOM at Aberdeen Proving Ground (MD) on November 22nd 2003 in according with the new CBRN norms. The Procedure is the N° RCT- CBRN – STP-001. In accordance with the Los Alamos Scientific laboratory, 25 member (male and female) Panel for testing of full face masks. LARGE of SGE 400/3 BB’s have been submitted to a complete test of leakage. 25 participants performed 11 standard exercises, 1 minute long each, using a routine devised to stress the face seal of the respiratory face-piece. During the test, each test subject is asked to perform:

- Normal breathing

- Deep breathing

- Turning head side to side

- Moving head up and down

- Reciting the rainbow passage

- Sighting the rifle

- Reaching for the floor and ceiling

- Getting on hands and knees

- Grimacing exercises

- Climbing the stairs at regular pace.

ME.ST.EL Certifications & Approvals:

| ISO 9001-2000 | International Organizations of Standardization |

| University of Genoa Certification | University of Genoa |

| Certificate of Approval No. 3082 | Centro Nacional de Medios de Protection, SPAIN |

| Certificate of Approval No. 1778 | Work Cover Authority, AUSTRALIA |

| Certificate of Approval, CA/156/89 | Health and Safety Executive, ENGLAND |

| CE Certification for category III in terms of European 89/686/CEE, in conformity with the harmonized EN 136:1998 CL3 | U.K. |

| HSE,DIN,EN 136 | U.K., Germany, Denmark |

| NATO ID: A-8515 | NATO |

What are ME.ST.EL Product Features?

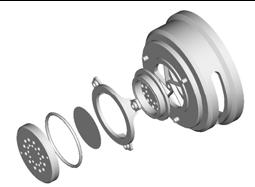

1. INTEGRAL FACE-PIECE

General features

This stiff, transparent structure is the actual supporting body of the SGE 400 protective mask. Its task is to take place of the rubber bodies previously employed by traditional designs to bear the weight to which the mask is subjected. This unit supports the head harness, valves, filters, regulators, etc.

The advantages of this innovation are:

a) Substantially reduced mask weight b) Better field of vision (practically the whole mask is transparent) c) the weight is held by a rigid structure, unlike the traditional rubber body which is flexible d) protection of the face is guaranteed by the impact and cut resistant structure e) Consequent lack of discomfort due to limitation of field of vision, the mask fits comfortably which increases the amount of time a person can wear it. f) Wearer can be easily identified due to the total transparency of the face-piece, helping to normalize conditions and maintain discipline.

The main part of the face-piece which consists of a large round surface in front of the eyes, is set back in the structure, thus keeping the overall dimensions to a minimum, reducing the risk of scratching and allowing the use of optical instruments so often used in today’s armed forces. The material used is a specially coated polycarbonate (SGE 400; SGE 400/3; SGE 400/3 BB only), which transmits no less than 90% of available light while absorbing U.V. rays.

Mechanical features

In the SGE masks, the entire body of the masks are made of a strong, rigid material (polycarbonate) and is therefore able to allow full protection for the face and eyes against extremely violent impacts. Laboratory tests have been carried out proving that the polycarbonate body is left unharmed by a 6.35 caliber bullet hitting it at a speed of more than 150 m/seconds. This means that the whole face is given the same protection afforded by the protective helmet.

Resistance to chemical agents

Treatment of the outer surfaces (SGE 400; SGE 400/3; SGE 400/3 BB only) makes the polycarbonate resistant to aggressive substances. Samples of the treated material have been subjected to mustard gas penetration tests. After over 50 hours, mustard gas failed to penetrate through the tested specimens. The treated face-piece may also be decontaminated an unlimited number of times without deterioration, using all the normal decontamination methods including immersion in boiling water.

Material used

Face-piece Transparent polycarbonate Treatment (SGE 400; SGE 400/3; Polysiloxane resin SGE 400/3 BB only)

Due to the use of an integral load-bearing face-piece, it was possible to make the rubber face-seal much lighter, as its only function is to act as a seal. Traditional masks consist basically of a load-bearing rubber structure fitted with two sealed eye-pieces, and since the rubber body has to bear the weight of all the accessories attached to the mask it has to be made rigid and thick (heavy and uncomfortable) and will therefore not adhere comfortably to the wearer’s face. Our face-seal, on the other hand, is made of very soft rubber with a supple bellows type structure which allows perfect sealing and a very high degree of comfort even after very prolonged use. The bellows type structure also allows it to adjust easily to all face shapes, so that it is no longer necessary to stock large numbers of different sizes of masks, many of which will go unused.

The face-seal has a seat into which the edge of the load-bearing face-piece is inserted, and the coupling of these two parts is ensured by the fixing rim. As a whole, the straps, face-seal and stiff body of the mask together provide far more comfort than traditional masks. In the case of traditional flexible rubber bodies, the tensile stress exerted by the ends of the straps are discharged only on the points where these join the body. In order to obtain uniform sealing all around the edge of the mask, it is therefore necessary to pull the straps very tight Naturally, this situation is one of the greatest causes of discomfort when using traditional masks. SGE’s stiff body means that the effort applied by the straps is distributed evenly and perfectly all around the edges of the mask so that it is not necessary to tighten the straps excessively and uncomfortably.

Material Used

Platinum—catalyzed grade silicone rubber.

3. FILTER FITTINGS

The SGE masks have a threaded fitting for application of standard filters (DIN 3183, UNI 7246). The fitting is contained in a single unit which also comprises the exhalation valve. The shape of the internal ring nut allows perfect ventilation of the whole face-piece, preventing misting even at low temperatures.

Mechanical characteristics

The material used is black polyarilamide, created for aeronautical and aerospace requirements. In addition to a very high impact resistance, it is not affected by aging or atmospheric factors. Its abrasion resistance is such that after testing with over 3000 assembly/disassembly operations, the filter had sustained no wear.

Material Used

Technopolymer parts: Polyarilamide reinforced with mineral charges Membrane Polyisoprene mixture

As already seen, the exhalation valve is fitted onto the same unit containing the filter fitting. Externally the valve has a structure which, although it covers the whole membrane, still allows easy discharging of the exhaled air. The purpose of this covering structure is to keep a sufficient volume of uncontaminated air in continuous contact with the membrane.

6. MEMBRANES

The exhalation membrane has been made to require minimum effort even at very high flow rates. The excellent memory of the membranes has been achieved by a combination of good design and high grade material. Using blends containing butyl rubbers instead of the traditional natural rubber used by other manufacturers, causing a considerable increase in resistance to chemical agents, has been achieved.

7. ORAL-NASAL UNIT

The design of this component is critical to the effectiveness and comfort of the mask. Because it comes in direct contact with particularly sensitive areas of the face, the correct choice of shape and material was vital. The oral-nasal area of our mask is made of soft medical grade silicone rubber, designed specifically for use in contact with the human body for indefinite periods of time without causing irritation or allergic reactions of any kind. The shape is designed to provide optimum comfort and efficiency; the U shaped peripheral lip performs the following important functions:

- It adheres softly and evenly to the face, following its contours perfectly

- It has a sufficiently rigid structure to ensure effective sealing during inhalation

- It is sufficiently soft to open and swells under the slight pressure caused by exhalation, isolating the nose and mouth area perfectly from the rest of the mask.

Breathing valve system

Two very light inhalation valves are attached laterally to the oral-nasal unit, the lower part of which is connected to the auxiliary drainage valve. The front part of the oral-nasal unit is attached into the exhalation/speech/feeding valve unit. This union is obtained by using the rubber’s elasticity, guaranteeing perfect sealing, and in addition allows for the easy removal of the oral-nasal unit (for replacement or cleaning purposes) by hand without the need for any tools.

Materials Used

Membrane: Polysoprene Oral-nasal unit: Platinum-catalyzed medical grade silicone rubber

The fixing rim has the role of connecting the straps to the frame of the mask and at the same time fixing and locking the face-seal and the incorporated hood, if used. Once the rim is tightened in place by means of the special screw, it fits into a special seat in the frame of the mask. In this way, the pull exerted on the fixing points of the head harness is transferred and distributed evenly around the whole circumference of the mask, allowing perfect adjustment of its tightness for maximum comfort and optimum sealing on the face of the wearer. It should be pointed out that this is not possible with the traditional mask, as the pull exerted by the strap itself is secured, thus requiring the wearer to over-tighten the mask, drastically reducing the level of comfort.

Materials Used:

Rim: Polyamide 11 Head-strap: Nitril

9. CLEANING AND DECONTAMINATION

The mask design makes decontamination and cleaning easier. In fact, even when rubber is made of mixtures capable of providing a chemical shield, its structure does absorb and is penetrated by the contaminants. The SGE masks are made of two main parts: face shield and face seal. So the majority of the mask is made of plastic materials which are not permeable to aggressive agents, and are not penetrated by them in the least even after very long exposure times. It is advisable to clean the mask each time after use. This is easily accomplished by washing with soap and water. Hot water can also be used. The mask can be disinfected using non—aggressive disinfectants or by immersing it briefly in boiling water. At least once a year the inhalation and exhalation membranes must be checked, as well as the sealing gasket of the fitting on the mask.

How to measure my vest size?

- You MUST wear a complete uniform and gun belt

- DO NOT take any measurements unless you are wearing your duty belt

- Empty all shirt pockets and stand or sit comfortably while being measured

- Do not watch the person measuring you

- Stand or sit relaxed and look straight ahead. Do not slouch and do not "stand tall"

Vest Sizing Chart

PLEASE NOTE: Armor Panels require a 2' to 2 1/2" gap between the gun belt and the bottom of the vest when standing. This open area is necessary to prevent the vest from riding up while seated.

Helmet Sizing Chart